Designing and engineering the next generation of SHARPS containers.

Where it started…

Requirements

Product Requirements

Container and lid must be easily integrated into current wash system robotics

Should have similar design/aspect ratio as current Stericycle containers

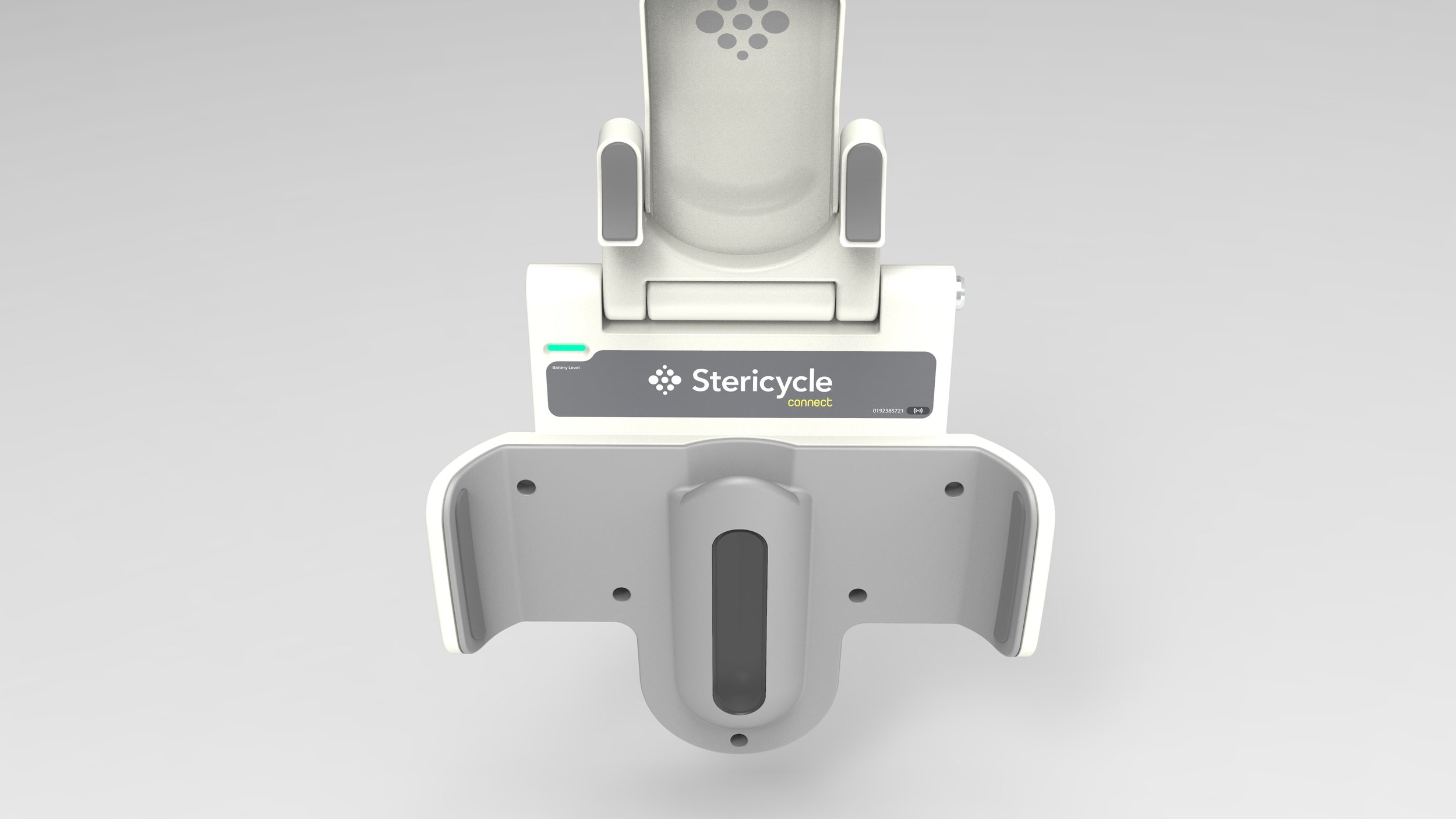

Containers should mount to vertical wall via a bracket and be removed horizontally

Bracket should allow for easy cleaning and have a locking feature

Table mount solution required to prevent tipping

Two types of lids needed- raised vertical drop and larger horizontal

Base colors required- yellow, red ,blue

Require marketing IML label on front- IML barcode label on other sides

Meets all requirements of ISO/CSA

One lid assembly fits both 2 and 4 gallon

Uses same clips as current containers

Similar design/aspect ratio

Leak Proof

ISO/CSA Requirements

Must be leak resistant when tipped over and for transport

Must not rupture or leak when dropped from 3.5 ft

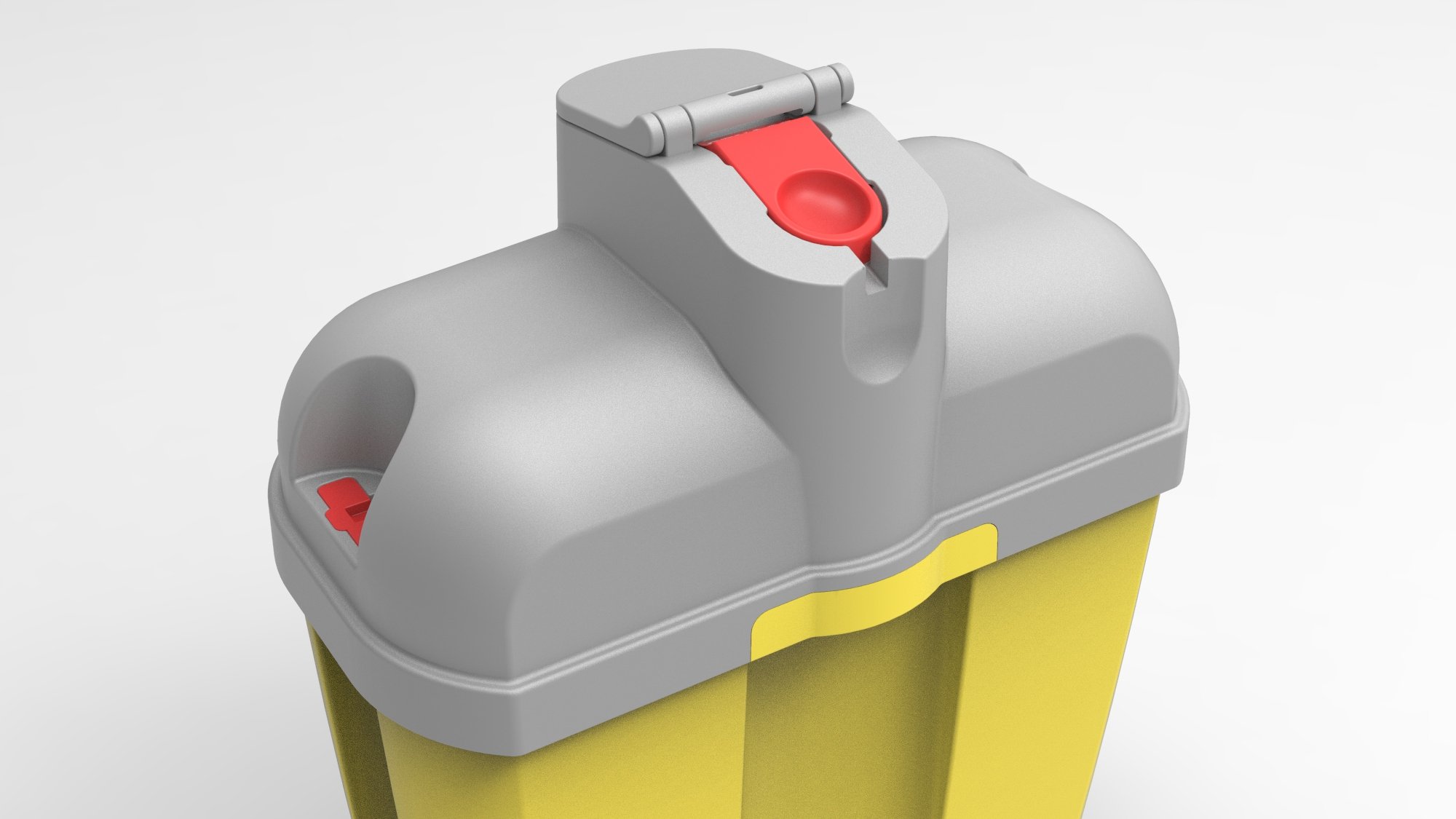

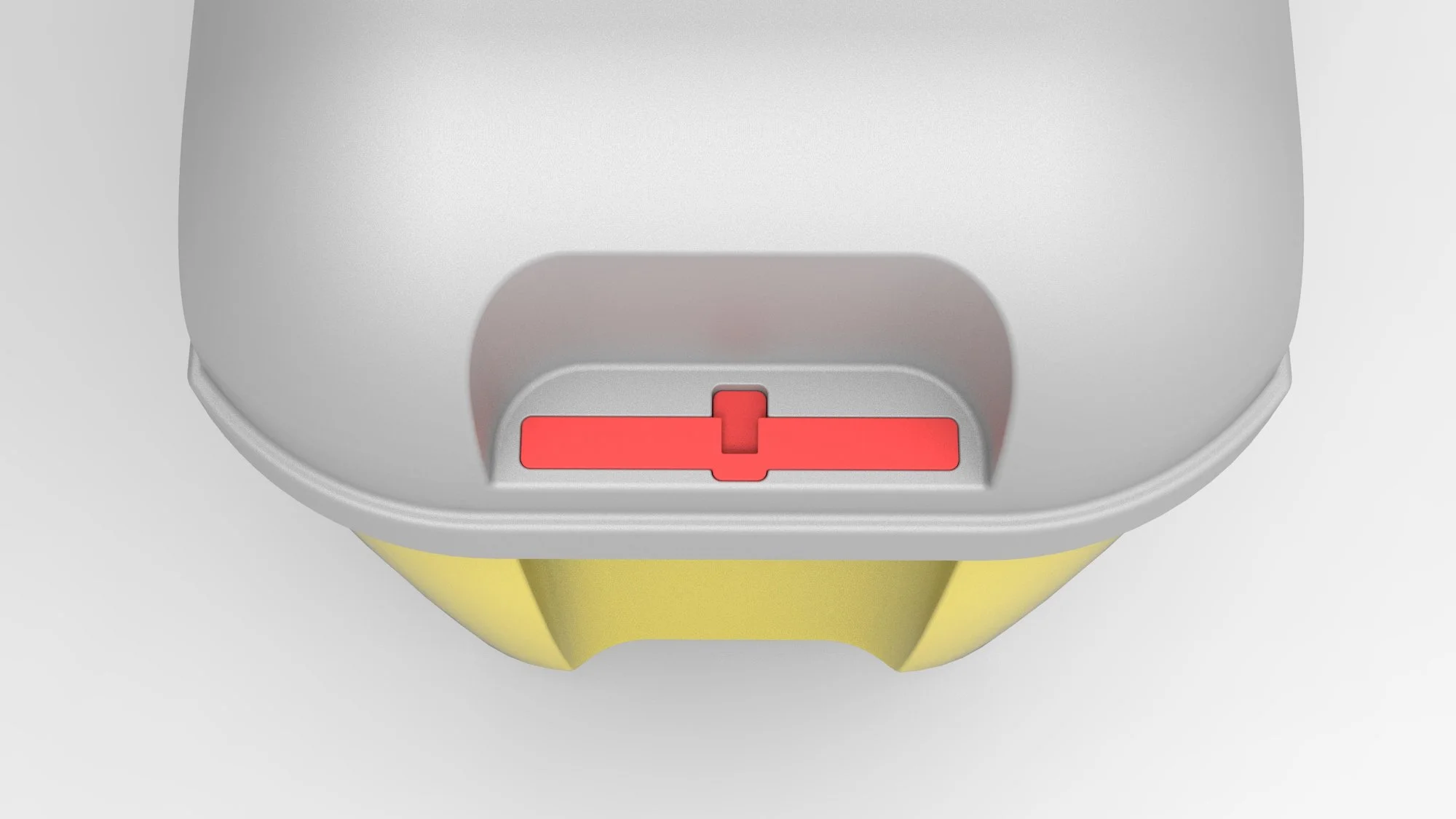

Must have integral aperture closure and have temporary and permanent locking feature

Must have clear window for “full” status

Must have integral handle

Must have permanent IML labels

Must have one-handed disposal of sharps

Must withstand 500 wash cycles and life cycle testing

Must prevent overfilling and accidental sticks

Must pass sharps puncture test

Must have mounting system to vertical wall

Container volume vs. “full” volume analysis

Understanding the Product’s Lifecycle

Automated washing and waste management

Competitive Analysis

Inspiration and Preliminary Concepts

Design drivers:

Iconic aesthetic

Cohesive form integrates lid and container

Sealing strategy embraced as brand element

Repeatable form language can be applied across products in line to ensure consistency

Reusable clips for lid

Integrated handle

Visual Messaging

The Chosen One…

Messages Stericycle’s vertical drop ceremony via cylindrical form and window

Contemporary, asymmetric label accentuates drop zone

Approachable, rounded forms embrace manufacturability and cleaning challenges

Cylindrical element (as cutout) becomes the affordance for the handle/ mounting feature

Flat front/back with rounded edges create a friendly design solution while also maximizing the volume of the container

Window in back used for the smart bracket/ level sensing

Designing a Family

Different lids for different functions

Common lids for 2 and 4 gallon containers, and 8 and 17 gallon containers. 3 different drop hole sizes needed with locking tops (and mechanical override).

Different sizes for different uses

4 different sized containers, 2,4,8, and 17 gallon.

Bio-hazard safety

All lids need to be disassembled by a robot. New designs needed to use existing robotic mechanisms and actuation points.

Engineering for Production

Mounting Solutions

Redefining wall and horizontal mounting

2 and 4 gallon containers can be wall mounted or surface mounted. 8 and 17 gallon containers sit in a dolly or on the floor.

Smart Wall Bracket

Passive Overfill

The big idea.

Safety: The design must physically prevent accidental and intentional access to waste

Sensing of Waste: Mechanisms must “tell” the product it's full without electronics

Triggering: The product must “passively” (unprompted by the user) react when it's full

Physical Barrier: This sensing and triggering must activate a method of preventing further insertion until the product is reset

Capping: A separate feature must be closed periodically to seal the product for transport and locked when appropriate