I specialize in turning concepts into production-ready products, using Solidworks and Creo/ISDX to create tooling-ready CAD data, while optimizing for manufacturability and functionality. My expertise spans construction strategy, electronics packaging, injection molding, other production processes, mechanism design, user interaction and experience, ingress protection, and functional prototype creation.

Product Engineering

Construction Strategy

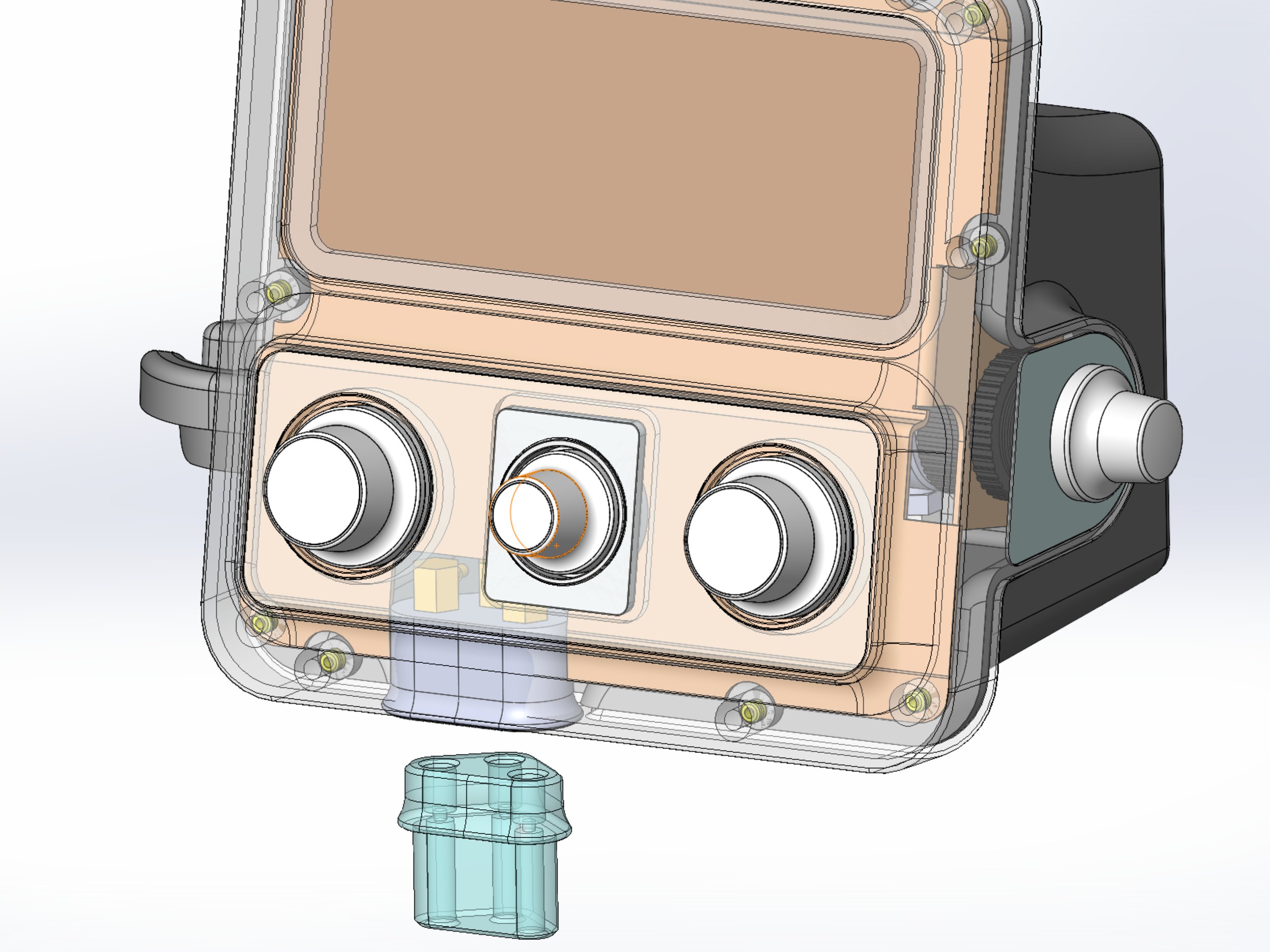

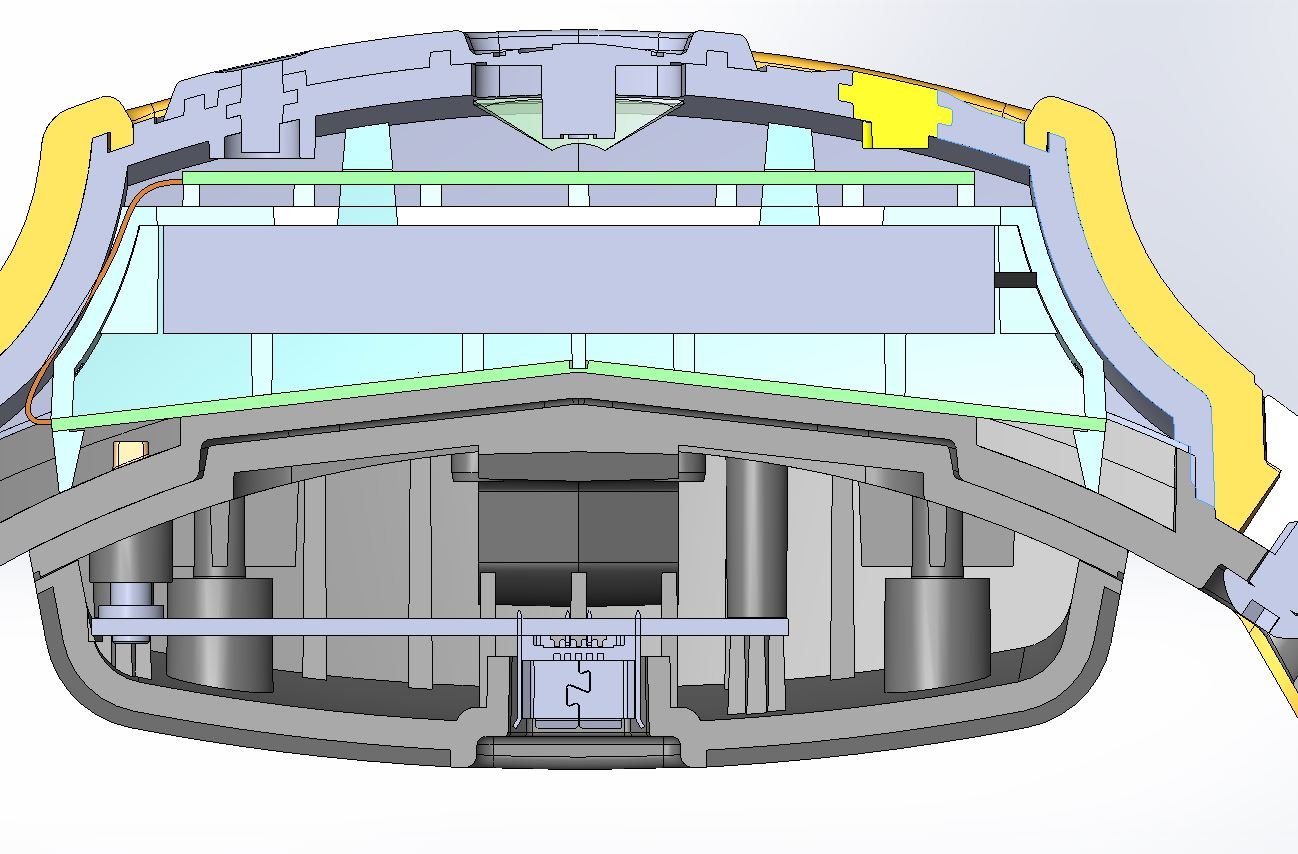

Internal component placement and architecture, manufacturing process analysis, feasibility and cost effectiveness, preliminary material selection, performance specifications, preserving aesthetics and design intent, preliminary part count, mechanical assembly points, assembly considerations, cleanability, and internal maintenance.

Electronics Packaging

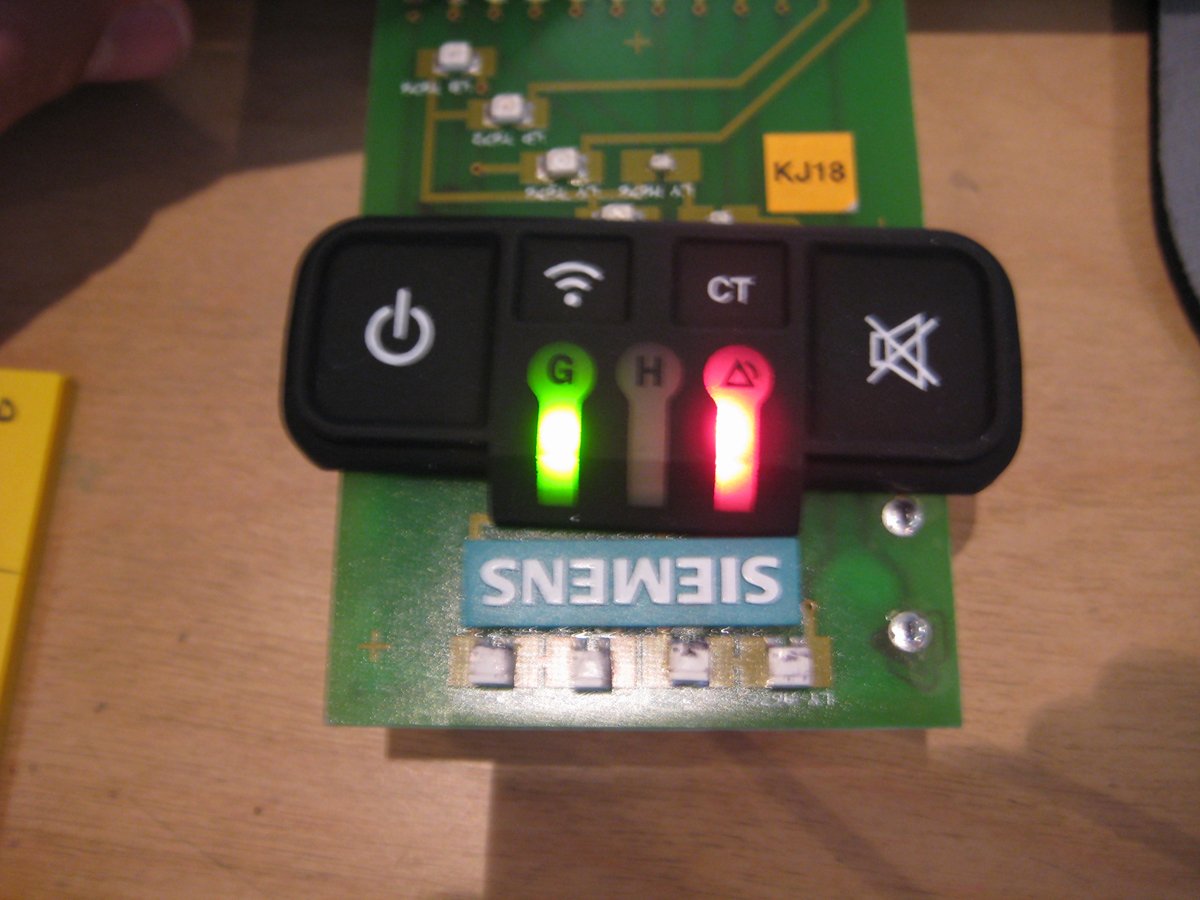

Display and PCB mounting, electronics thermal management, electronics isolation, enclosure venting, audio performance, microphones, PCB outline design and integration, battery doors and contacts, LED light pipes, wiring management, UX/UI touchpoints, and internal chassis design.

Injection Molding

Tooling ready CAD data (including complex organic surfaces), preliminary material selection, solutions for cosmetic imperfections, draft analysis and required draft for selected textures, production tooler collaboration, over molding, first article cosmetic inspection, and creating supporting 2D and CMF documents.

Other Production Processes

Knowledge of die-casting, aluminum extrusions, sand castings (match plates), silicone molding, co-extrusions, wire forming, sheet metal, ultra-sonic welding, and CNC machining.

Mechanism Design and Analysis

Defining the problem, objective, and constraints, conceptualize potential solutions, iterative problem solving, model analysis, and concept refinement based on testing.

User Interaction and Experience

In-depth expertise in engineering user experience touchpoints through the use of tactile feedback, materials, light, scale, color, graphics, texture, and sound (silicone keypads, Lexan overlays, LED light pipes, Hard and soft keys, Gore membranes, perception of quality).

Ingress Protection

Design and engineer IP rated products (up to IP 6/8) using compression sealing, wiper seals, ultra-sonic welded assemblies, and over molded components.

Functional Prototyping

Expert knowledge of 3D printing processes (SLA, SLS, FDM, PolyJet), proof of principle mockup fabrication, UX/UI evaluation, wearable mock ups, machining (mill and lathe), and TIG welding.